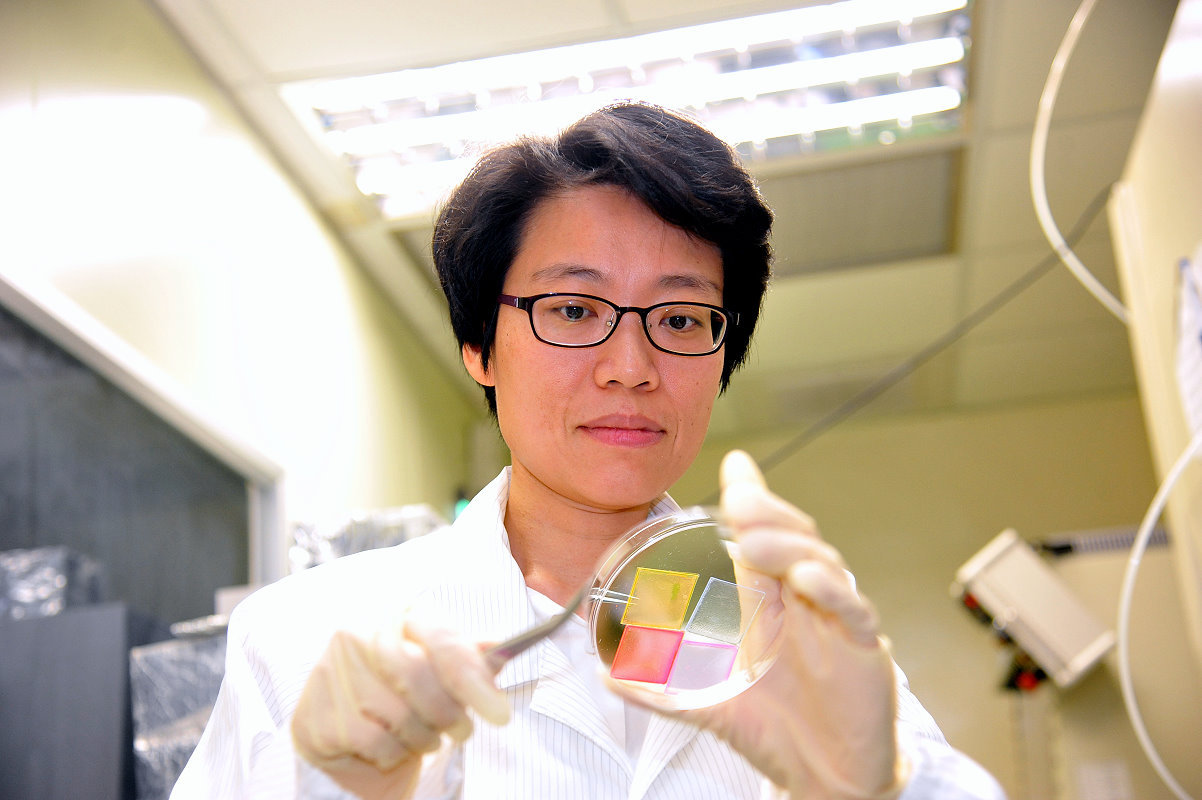

Using fish DNA to make optoelectronic components. Yu-Chueh Hung’s team establish a natural DNA process platform

The sensors that are most needed in the Internet of Things era, and the solar cells needed for green energy, could all be made of DNA. The research teams of the department of Electrical Engineering, institute of Photonics Technologies of NTHU, receive support from the Ministry of Science and Technology. They extracted the DNA of fish to produce photoelectric materials, and developed the world's first "light-sensing DNA nano-composite technology." Successfully established the only natural DNA material processing platform in Taiwan. It is expected to replace petrochemical materials and be used in the field of optoelectronic components.

Professor Hong said that due to resource depletion and environmental pollution, many industries around the world are thinking about reducing their dependence on petrochemical materials. Especially, bio-matrix-based materials receive many attentions due to their natural and sustainable environmental advantages. For instance, companies like Coca-Cola, extracted sugar cane to improve the packaging material of the bottle.

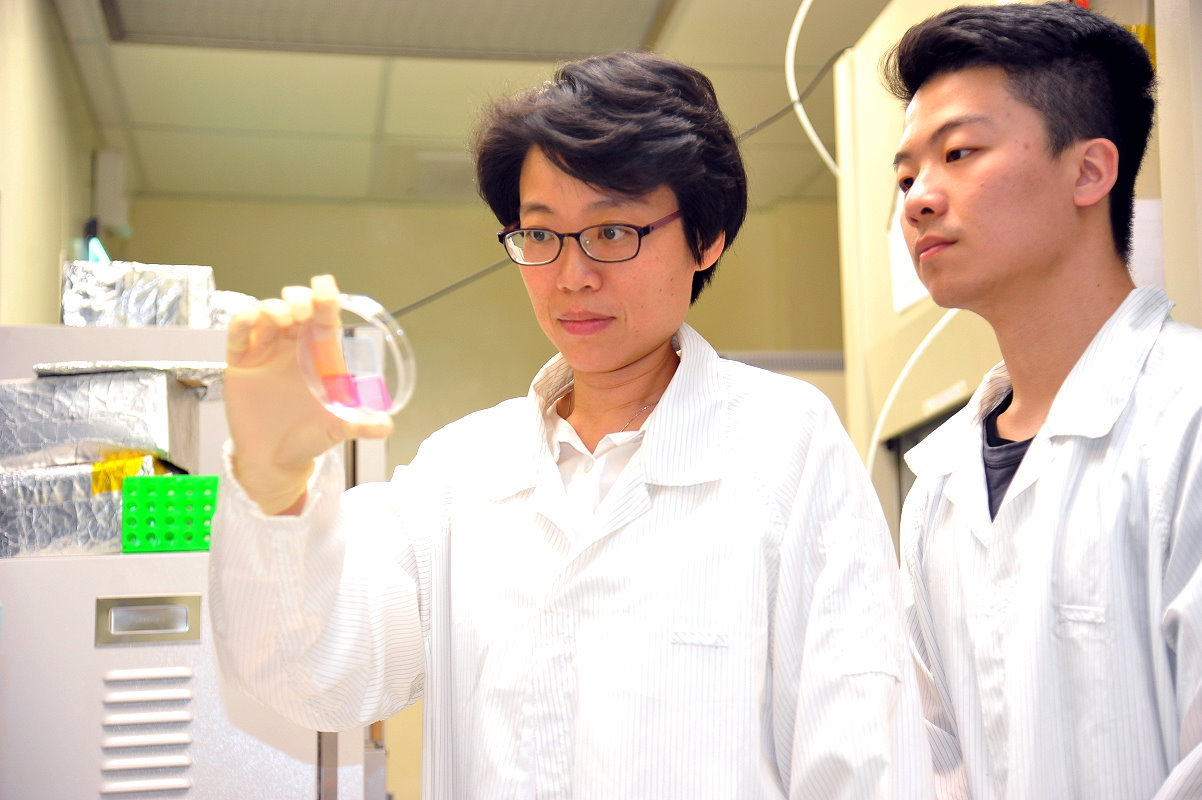

At present, photoelectric components such as sensors and solar cells are mostly made of semiconductor materials, and few people think that bio-DNA molecules can be used as materials. "In fact, biological DNA is not only large in quantity, easy to obtain, but also has many characteristics to be developed."

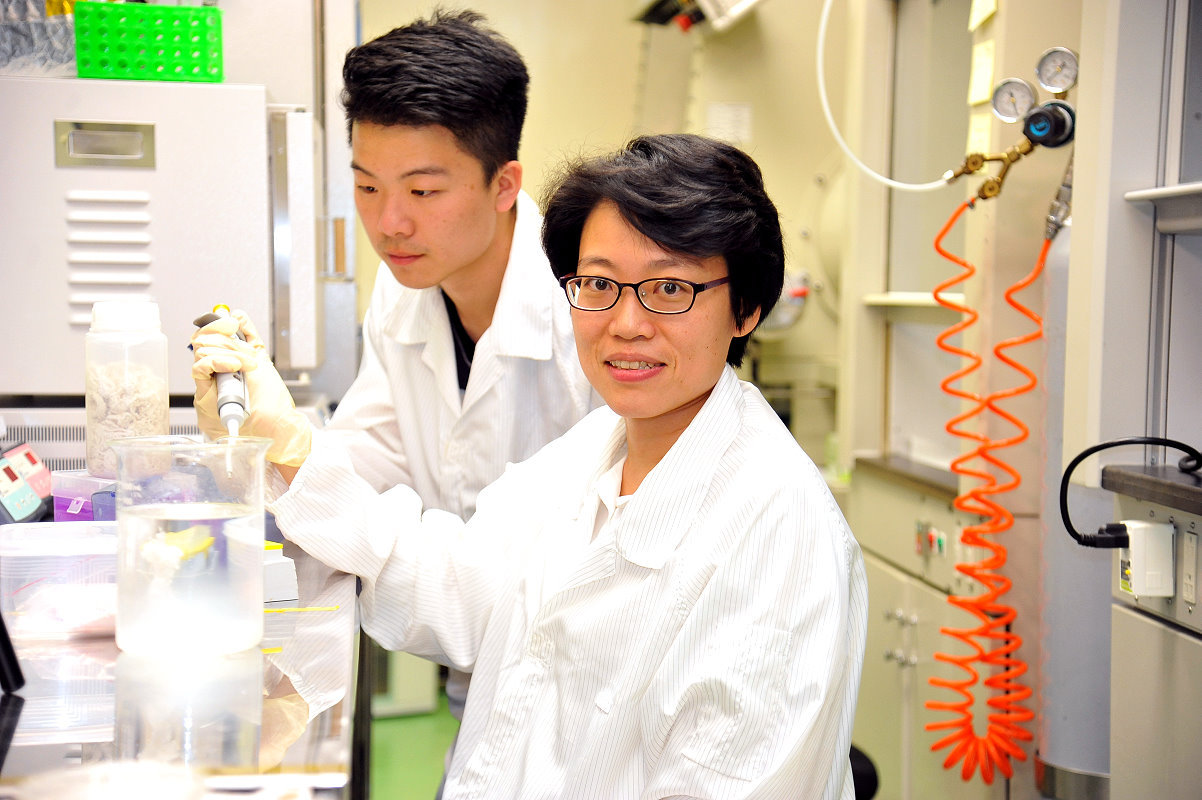

The development of this technology firstly requires DNA. After the research team obtained DNA from fish eggs and surimi, it extracted DNA by homogenization, impurity removal, alcohol precipitation and other techniques. Using DNA properties, a series of new surfactant-modified DNA molecules and innovative process technologies have been developed, which can be applied to nano- to micro-scale optical films, optoelectronic components and sensors in the future.

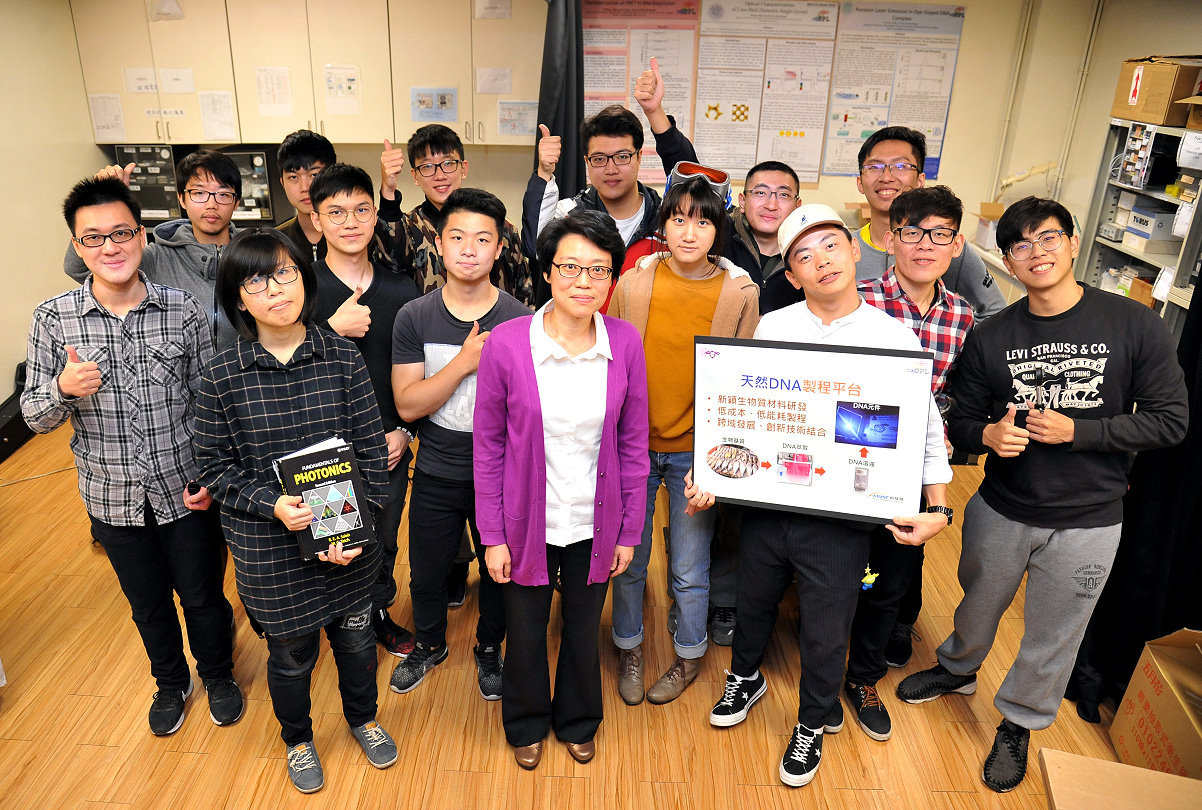

In order to confirm whether DNA can be used as a material for making optoelectronic components, Professor Hong not only survey a lot, but also took students to visit domestic laboratories. They even went to the Department of Chemical and Biological Sciences of the University of Cambridge, United States Air Force Research Laboratory Materials and Manufacturing Bureau. Having cross-domain, multinational teamwork. She said that discussing with experts in different fields not only learns new technologies, but also inspires teachers and students to think and solve new problems.

Professor Hong said that she is very grateful to some of her students. For this study, they took courses in the Department of Biosciences, Chemistry, and Materials, and learned the techniques of extracting biological DNA and material synthesis. Some students even stood by in some laboratories. Bringing new research methods from various fields back to NTHU. "The most valuable thing is that they are also responsible for teaching the rest of the team."

Professor Hong Wei believes that the students in the electrical engineering department have a very flexible background. They can learn, integrate and apply quickly regardless of the cross-border areas. "This is the advantage of the EE people!" She also hopes that the ongoing cross-disciplinary research will be able to create more sparks and more technology possibilities.

On the press conference, president of department of Engineering and Technologies of the Ministry of Science and Technology, Shawn Hsu, pointed out that many electronic materials recycling requires a lot of resources. The government now attaches importance to green energy technology and circular economy. If the electronic components are initially produced with the introduction of decomposable and recyclable materials, it can reduce costs and reduce environmental pollution.